300kg/h Automatic Garlic Powder Manufacturing Processing Plant

The garlic powder manufacturing plant can process different garlic products into garlic powder. It is relatively simple to use dried garlic slices as raw materials, and the garlic powder can be obtained directly by grinding with a mill. There is another kind of garlic head, which has many processing techniques, mainly including garlic cloves, garlic peeling, garlic cleaning, garlic air drying, garlic slices, garlic drying, and dehydrated garlic flakes grinding. After grinding, we can also configure different garlic powder packaging equipment according to customer’s packaging needs. According to your current situation of large-scale products and your specific needs such as processing capacity, we can provide you with a customized garlic powder production line! !

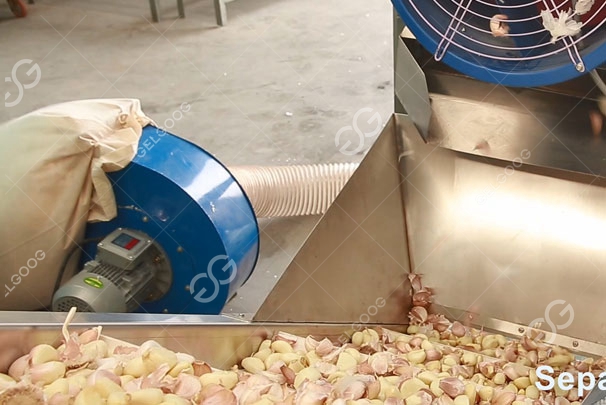

Garlic Powder Processing

Garili Powder Process flow: material selection→peeling garlic→slicing→rinsing→dehydration→drying→finished product.

(1) Selection of raw materials. Mature, complete, clean, free from insects, mildew, and dry garlic with a diameter of 4 to 5 cm should be selected as raw materials. Freshly harvested wet garlic should be dried to reduce moisture content.

(2) Peel the garlic. Before peeling the garlic, use a knife to flatten the root of the garlic, otherwise the color near the root of the garlic will become dark after drying; at the same time, dig out the wound discoloration and spots on the garlic clove, and remove the chaffed garlic cloves. The garlic can be peeled dry directly or soaked in water and then peeled wet. When wet peeling, the soaking time in water is generally about 30 minutes, too long will affect the color and flavor of the product. Be sure to peel off the thin garlic coat attached to the garlic cloves, then rinse with water to clean the garlic cloves.

(3) Slicing. Use a slicer to cut the cleaned garlic cloves into slices. The thickness of the sliced fresh garlic slices should be about 2.2 mm, and should be uniform, complete and free of debris.

(4) Rinse. The chopped garlic slices can be rinsed in a tank or pool until the garlic slices are clean and the pool water becomes clear.

(5) Dehydration. Dehydrate the cleaned garlic slices in a centrifuge for about 1 minute. Note that the time should not be too long, otherwise the garlic slices will easily become chaff (empty, soft), and small bubbles will appear on the surface, which will affect the yield and quality of the product.

(6) Drying. Generally, the drying room is used for manual drying. Before baking, spread the garlic slices after the water dumping for a short time, and then put them into the baking tray. It is advisable to spread the garlic slices per square meter of the baking tray area.

(7) Grinding. Grind the dehydrated garlic slices into 20-120 mesh garlic powder through a universal mill.

Garlic Flake Drying Process Requirements

The thickness of the garlic slices is very important during the slicing process. If the slices are too thick, not only will the drying efficiency be slow, but the color of the garlic slices will deteriorate, affecting the quality. If the slice is too thin, when the thickness is 1MM, the baked garlic slices will not be in good shape and have a high fragmentation rate. When the thickness of the garlic slices is 1.5-2.5MM, the dried color and appearance will be good, and the allicin retention rate will be higher. When the height is 50-65%, the efficiency, quality and allicin content of garlic slices drying machine reach the best point.

Spread the garlic slices evenly on the stainless steel material tray, control the temperature at about 55-60°C, and drying for 6–8 hours. During the drying process, pay attention to the drying of the garlic slice drying room, and the amount of hot air and moisture should be stable. When drying in the later stage, due to the fine garlic fibers and the thick liquid in the garlic slices, the moisture migration and evaporation of the garlic slices becomes slow until the time of drying. The garlic slices are dried to a moisture content of about 4-6% to complete the drying. During the drying period, the time and temperature must be strictly controlled to avoid excessive drying time and high temperature, which will damage the dry color, appearance and nutritional value of the garlic slices and affect the quality of the garlic flakes.

Due to the uneven size of dried garlic flakes, the moisture content is slightly different. In order to achieve a consistent moisture content, a moisture balance is required. Put the dried garlic flake in a plastic bag, tie the bag, and place it on the shelf for about 3 days.

Youtube Video

Garlic Powder Processing Machine Advantages

1.Good product quality: it is about 38-52°C lower than the traditional drying process, the color of the dehydrated garlic slices is better, and the internal quality is stable;

2.High drying efficiency: the time required for dehydration of garlic is no more than 8H, generally it can be completed from preheating to 4H when the product is produced, the drying time is short, and the single drying amount is large;

3.Long storage period: It protects the color, aroma, taste, individual form and active ingredients of dried products more effectively than any traditional drying equipment, and improves the qualified rate of finished products and reduces the defective rate of dried products.