Fully Automatic Red Chili Powder Production Processing Line

The chili powder production line is mainly used for the processing of seasoning /spices powder, chili powder and crushed various meshes in the food industry. The design is reasonable, the structure is compact, the floor space is small, and the installation is convenient. The chili powder grinding process adopts the international advanced grinding machine to grind the dried chili, with stable performance and high output, ensuring the coloring of the chili powder. Can be applied to many less oily spices such as chili ginger, garlic, pepper, fennel, cumin, turmeric, etc. The chili powder production line is very popular in Sri Lanka, Malaysia, the Philippines, Thailand, Mexico, Nigeria, Bangladesh, Rwanda, South Africa and many other countries, helping customers who develop chili deep processing business to obtain continuous commercial profits! !

Chili Powder Processing

Process flow of chili powder production line: The chili powder production line includes the processes of pepper removal, seed removal, drying, milling, granulation, and quantitative packaging. Professionally provide pepper crushing equipment pepper crusher. This set of equipment is an advanced equipment for processing chili, and has been successfully applied to the production line of edible chili powder.

The technological process of chili powder production line is as follows:

1. Impurity removal: The pepper stone removal machine is used to remove impurities such as stones in the pepper, which has the characteristics of easy operation and high output.

2. Iron removal: The equipment used in this process is an automatic iron removal machine, which has a 10500 Gauss strong magnet and uses pneumatic methods to remove chili powder and iron powder in the chili section.

3. Seed removal: The pepper seed removal machine is mainly used for the separation of pepper pulp and pepper seeds. It can process 1000kg-2000kg per hour. It is a special equipment for pepper deep processing.

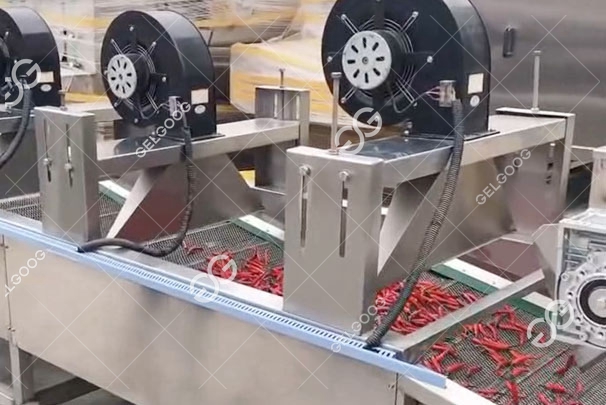

4. Drying: The chili pepper heat pump continuous dryer is not affected by the external environment, weather, season and climate, can work continuously for 24 hours, and can well guarantee the quality, color, appearance and capsaicin of the dried chili pepper.

5. Grinding: The double-rotor pepper grinder is used to make the pepper into fine powder, which has high output, low power consumption, and is clean and hygienic.

6. Granulation: High-quality granulation system, continuous operation and automatic discharge.

7. Quantitative packaging: The ground chili noodles should be completely cooled before being stored in a sealed bag, otherwise it is easy to regain moisture and deteriorate. Bag qualified chili powder or chili granules, weigh and seal.

Chili Pepper Drying Process Requirements

Under normal circumstances, the peppers in the production area are purchased in large quantities. After many farmers send the peppers to the manufacturers, the manufacturers will use the pepper heat pump dryer to dry the chili peppers:

First: Dry the peppers with a moisture content of up to 75% to 85% by stepping on the pile and sweating to a moisture content of about 50%, and then use a pepper dryer for the second drying.

The second stage: secondary re-drying with pepper dryer: Due to the difference in quality and maturity of peppers, individual peppers that cannot be dried in the first drying operation should be selected immediately for re-drying operation. The water content of pepper raw materials is relatively high, generally 75% to 85%. Dry with 40-60 ℃ hot air, the initial relative temperature is lower than 70%, the relative humidity will drop below 52% after 5 hours, and the relative humidity will be lower than 40% after 12 hours.

The third stage: re-moisturizing before packaging: After the drying process of peppers is completed, the water content is very low, the texture is brittle and easily broken, so it should be placed indoors for re-moisturizing, so that the dried peppers can absorb a certain amount of water and make them softer , so that the packaging can be stored.

Precautions:

The key to the control of pepper dryer is the control of moisture content. Under normal circumstances, the moisture content of dried peppers is about 14%. If the moisture is too high, it will easily make the peppers moldy and deteriorate. If the moisture is too low, the dried peppers will be easily broken. Control is appropriate.

Youtube Video

Chili Powder Making Machine Advantages

1.The air outlet of the fan is equipped with a pulse dust collector to make your working environment cleaner;

2.The chili powder making equipment adopts an all-steel structure, with beautiful appearance, convenient installation and small footprint;

3.Screening powder adopts high-efficiency double-silo flat screen, and the screen is made of stainless steel wire mesh, which is not easy to block;

4.The coarsely pulverized chili particles are powdered by the international advanced air pressure milling machine, which has stable performance, high powder yield, and can ensure the chromaticity of chili powder;

5.The whole machine adopts pneumatic conveying, all of which are conveyed by negative pressure, which can not only prevent the leakage of odor, but also effectively reduce the dust in the workshop, and can play a certain drying role in the milling process;