Industrial Dried Mango Production Processing Plant

The dried mango processing plant replaces the cumbersome manual mango processing procedures, greatly improves the efficiency of mango drying and processing, saves labor costs, and makes the entire mango drying process and drying quality more controllable. Dried mango is prepared by selecting materials, peeling, slicing, hardening, drying and packaging. Its color is bright, with orange, orange or golden yellow. The surface of each dried mango is dry and non-sticky, with a strong mango aroma, sweet and sour delicious, nutritious, sweet but not greasy snack food.

Dried Mango Processing

Dried Mango Process flow

Raw material selection→cleaning→peeling and slicing→color protection treatment→drying→packaging.

Selection of raw materials Ripe fresh mangoes such as Luzon Mango or Zihuamang or wild mango are very suitable for processing and have good color. The first is that the meat is hypertrophic to improve the yield. The mango ripeness is 8 to 9. If the ripeness is too low, the color and flavor of the mango will be poor, and if it is too ripe, it will easily rot.

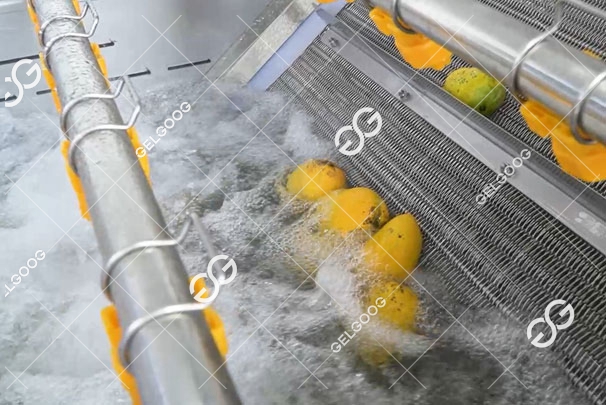

Cleaning: Pour the mangoes into the flowing clean water tank and clean them one by one, further remove the unqualified fruits, and finally pack them in plastic baskets according to their size and drain the water.

Peeling and slicing Use a stainless steel knife to manually peel off the outer skin and repair the scars. The surface is required to be smooth and without obvious water chestnuts. The outer skin must be cleaned. The causal skin contains a lot of tannins. If it is not cleaned, it is easy to brown during processing, which will affect the color of the finished product. The peeled fruit is sliced longitudinally with a sharp blade, and the thickness is about 8-10 mm. The pits of the remaining pulp can be sent to beating to make juice.

Color protection treatment adopts sulfur fumigation or sulfur immersion method.

Drying Put the color-protected raw materials on the drying rack evenly (drain the water first for the sulfur-dipping treatment), and put them in the heat pump dryer to dry.

Softening and packaging When the moisture content of the product reaches the drying requirements, it is generally about 15% to 18%. Put the product in an airtight container and let it soften for about 2 to 3 days, so that the moisture content of each part is balanced and the texture is smooth. Soft and easy to pack.

Mango Drying Process Requirements

Due to the high sugar content of fresh mangoes, it is difficult to make dried mangoes. The temperature should be well controlled, neither too high nor too low, and the humidity of the drying room should also be well controlled, otherwise the color and taste of the mango will be affected. Problems occur, and drying time is also one of the key parameters.

Mango drying requires the temperature, humidity and time of the three sections of the powder to be set:

The temperature of the first zone is set at 45°C, the humidity is set at 65%RH, and the time is set at 4 hours;

The temperature of the second zone is set at 55°C, the humidity is set at 42%RH, and the time is set at 6 hours;

The temperature of the three zones is set at 62°C, the humidity is set at 26%RH, and the time is set at 22 hours.

Drying can then be automated.

Youtube Video

Dried Mango Processing Machine Advantages

1. The mango drying process is well ventilated and heated evenly.

2. The mango drying process is safe and reliable, and there is no danger of overheating or burning during the drying process.

3. Controlling the corresponding parameters of mango drying can effectively solve the problems in the drying process.

4. The mango is dried by a heat pump, which has low energy consumption in the drying process and effectively reduces operating costs.

5. Automatic temperature and humidity control with high accuracy. Effectively avoid the phenomenon of incomplete drying or excessive drying caused by manual operation, reduce labor intensity and reduce operating costs.