Drying seaweed is a crucial process in seaweed production, which plays a significant role in the quality and shelf life of the seaweed. Seaweed is a rich source of vitamins, minerals, and antioxidants and is consumed by people around the world for its health benefits. In this article, we will discuss the drying seaweed production process in the factory.

The drying process involves removing moisture from the seaweed to increase its shelf life and prevent spoilage. There are different methods of drying seaweed, including sun-drying, oven drying, and air drying. However, in the factory, the most commonly used method is hot air drying.

The first step in the drying seaweed production process is to harvest the seaweed. The seaweed is usually grown on ropes or nets suspended in the sea, and it is harvested by cutting the ropes or nets and removing the seaweed. After harvesting, the seaweed is washed thoroughly to remove sand, salt, and other impurities.

The washed seaweed is then blanched in boiling water for a short period to remove any remaining impurities and to soften the seaweed. The blanching time depends on the type of seaweed, but it usually takes a few minutes. After blanching, the seaweed is drained and cooled down.

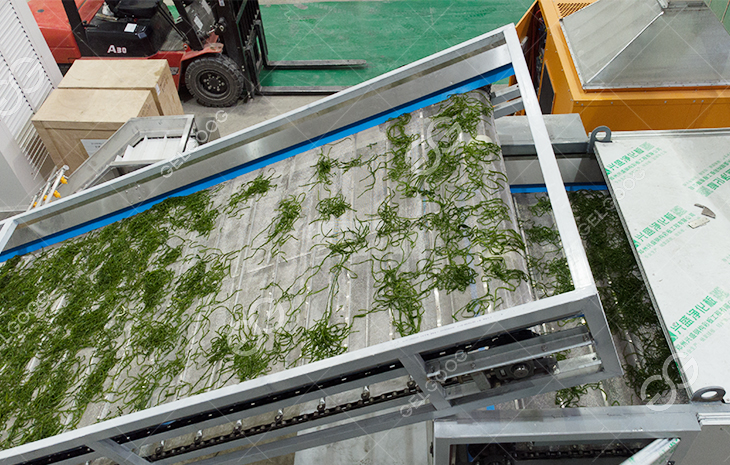

The next step is to dry the seaweed. In the factory, hot air is used to dry the seaweed. The seaweed is spread out on a conveyor belt, which passes through a drying chamber. The drying chamber is heated to a temperature between 50°C to 60°C, and the hot air is blown through the chamber to dry the seaweed.

The drying time depends on the type of seaweed, the thickness of the seaweed, and the temperature of the drying chamber. Generally, it takes around 4 to 6 hours to dry the seaweed fully. During the drying process, the seaweed is turned over periodically to ensure that it dries evenly.

After the seaweed is dried, it is sorted and packaged for distribution. The dried seaweed is inspected for quality, and any damaged or discolored seaweed is removed. The seaweed is then weighed and packaged in plastic bags or paper bags.

The packaging of the seaweed is crucial to maintain its quality and shelf life. The packaging should be airtight to prevent moisture from entering and to prevent the seaweed from becoming damp. The seaweed is usually packed in small portions to make it easy for consumers to use.

In conclusion, the drying seaweed production process in the factory involves harvesting the seaweed, washing it, blanching it, and drying it using hot air. The drying time depends on the type of seaweed and the temperature of the drying chamber. After drying, the seaweed is sorted, inspected for quality, and packaged for distribution. Proper packaging is crucial to maintain the quality and shelf life of the seaweed. Dried seaweed is a popular ingredient in many dishes and is known for its health benefits.