Description

The kiwi fruit drying machine effectively utilizes the environmental heat source, and has the advantages of high efficiency, energy saving, cleanliness, safety and stability. Compared with the traditional drying process, the inner wall is all stainless steel, which can effectively prevent microbial contamination. It is equipped with a self-developed air distribution system to effectively preserve The taste and quality of kiwifruit. And the unique low-temperature drying process is adopted to dry evenly, so that the kiwifruit maintains its natural color, original fruit aroma and vitamins and other nutrients.

Kiwi Fruit Drying Machine Advantages

1. Airtight and dry, dust and mosquitoes cannot enter, clean and hygienic;

2. No water vapor, directly drain out, no water vapor, keep the board room dry;

3. Safe heat pump dehydration technology, no need to worry about electric shock or fire;

4. Energy saving Complete energy recovery, not affected by ambient temperature and humidity;

5. Convenient, can be mixed dry and wet, pick and place at any time, plug and play, no installation;

6. Fast and closed cycle, no energy is lost to the outside, and the drying speed is accelerated;

7. One machine can be used for multiple purposes. It can not only dry kiwifruit, but also other agricultural products.

Heat Pump Dryer Parameter

| Item | Heat Pump Dryer Parameter | |||

| Model | GG-3P | GG-7P | GG-15P | Unit |

| Environment temperature | -10-43 | -15-43 | -15-43 | ℃ |

| Drying temperature range | 30-75 | 30-75 | 30-75 | ℃ |

| Rated power | 4 | 12 | 21 | Kw |

| Maximum power | 10 | 18 | 33 | Kw |

| Power supply form | 380/3/50 | 380/3/50 | 380/3/50 | V/Ph/Hz |

| Temperature control accuracy | ±1 | ±1 | ±1 | ℃ |

| Electric heating power | 6 | 6 | 12 | Kw |

| Controller | Single chip microcomputer/PLC+color screen control | |||

| Noise level | ≤75 | ≤75 | ≤75 | dB(A) |

| Capacity | 100-200 | 300-700 | 800-1500 | Kg |

| Dehydration capacity | 9 | 21 | 43 | Kg/h(=50℃,80%) |

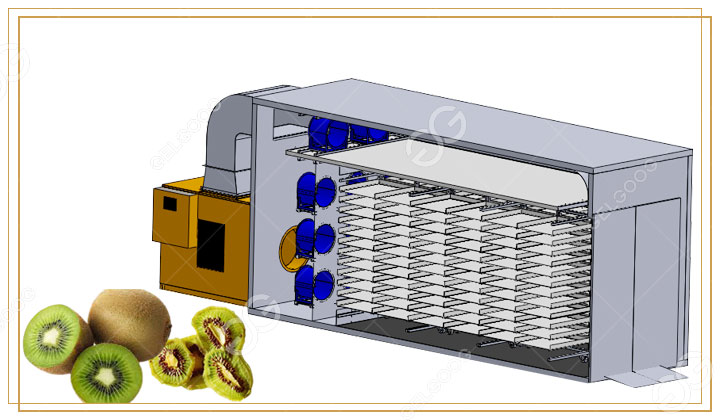

Kiwi Fruit Dryer Machine Structure

1. Polyurethane sandwich panel warehouse

Provide insulation for the kiwi in the oven

2. Fan wall

Provide wind energy for the materials in the drying room and bring out the moisture in the kiwi.

3. Top blower machine

Control the start and stop of the drying room, control the temperature, humidity and dehumidification time of the drying room, and provide heat energy for kiwi drying

4. compartment

After the wind from the fan wall passes through the material, it is then led back to the fan wall by the partition, so that the air volume before and after the drying room is consistent, and the purpose of drying the material evenly is achieved.

Reviews

There are no reviews yet.