The dry onion flakes making process: raw material selection → cutting tips → root digging → peeling → washing → slicing → rinsing → draining → sieving → drying → selection → inspection → packaging.

a, Material selection: carry out appearance inspection on fresh onion heads, remove rotten ones and those with pests and diseases;

b. Root cutting and peeling: use the onion head and root cutting machine to remove the head and tail of the onion, and then use the chain onion peeler to remove the onion skin;

c, Cleaning, slicing and drying: the fresh onion heads are cleaned and dried by an integrated cleaning and air-drying machine, and the air-dried onions are sliced with an onion slicer to obtain onion slices with a thickness of 25mm;

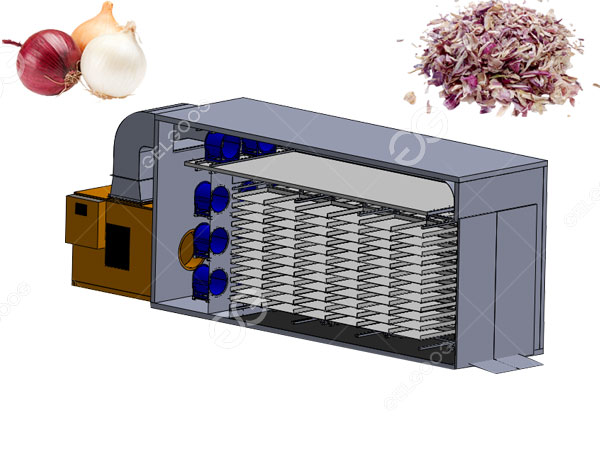

d, Drying: put the onion slices into onion drying machine, and dry them for 35 hours at a temperature of 50-60 ℃, until the water content of the onion slices is 24% and take out;

e, Inspection: the heavy metals in the dried onion slices are inspected by a metal detector;

f. Packaging: The inspected onion slices are sealed and packaged through the packaging bag under aseptic conditions, which is the finished product.

Dehydrated onion flakes include yellow onion slices, white onion flakes and red onion slices, which not only retain the original color and nutrients of onions, but also are easier to preserve than fresh onions, and are very popular among consumers in the international market! Do you also want to start a dehydrated onion flakes business, please feel free to contact us online to get a free quote for dehydrated onion processing equipment! !