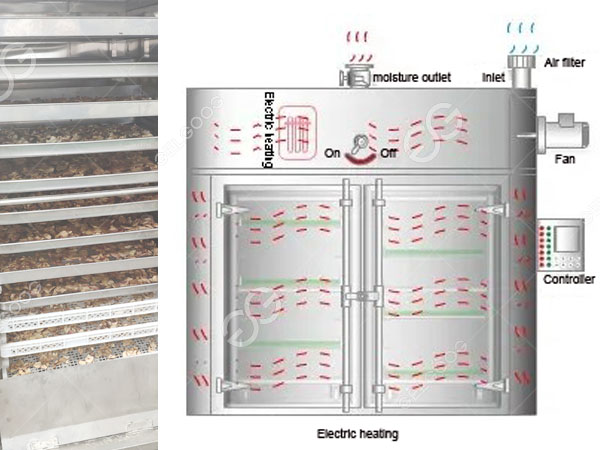

The hot air circulation oven dryer adopts a high temperature circulating fan, and the forced hot air heated by the electric heating tube or the Yan steam heat exchanger circulates in the box, which enhances the transfer of heat, improves the rate of moisture emission, and shortens the drying time. The whole box adopts a fully enclosed structure, and the hot air box circulates, and the humid and hot air is reasonably discharged and fresh air is supplied.

Hot Air Circulation Drying Oven Principle

The air source is driven by a circulating air supply motor (using a non-contact switch) to drive the wind wheel through the heater;

Then the hot air is sent out, and then goes to the inner room of the oven through the air duct;

The used air is sucked into the air duct to become the air source for recirculation and heating for use;

To ensure room temperature uniformity.

When the temperature value swings due to the door opening and closing action, the air supply circulation system quickly returns to the operating state until it reaches the set temperature value.

The oven dryer is equipped with an automatic temperature control system with precise temperature control.

There is an adjustable air distribution plate in the box, and the temperature in the box is uniform.

The low-noise and energy-saving built-in circulating fan is used to balance the operation and greatly reduce the noise and heat loss of the equipment. The air inlet is equipped with an air filter and is equipped with a dehumidification device as standard.